5% Borated Polyethylene

JCPE5

JCPE5 is a 5% boron loaded polyethylene neutron shield – HMW grade. Specifically developed for neutron shielding purposes in nuclear installations; its optimal boron content of 5% provides excellent attenuation of thermal neutrons, thus reducing the levels of capture-gamma radiation.

JCPE5 has a high hydrogen content, making it an effective fast neutron shield, slowing down fast neutrons to low energy thermal (slow) neutrons, which are then absorbed by the added boron compound.

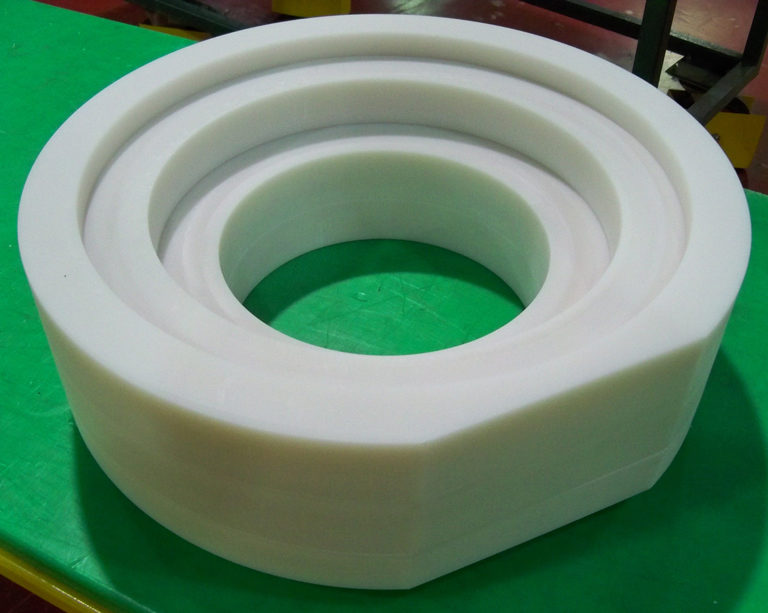

JCPE5 5% Borated Polyethylene is typically used in neutron shielding applications where low and intermediate-levels of neutron flux are expected, but elevated temperatures are not. JCPE5 is available in a wide range of form factors including sheets, bricks, cylinders, pellets, and other custom shapes.

It is easily machined using common wood and metalworking tools. John Caunt Scientific can not only provide custom machining but can also pour JCPE5 into custom made moulds to provide application-specific shielding forms.

Features at a glance

- available as slabs, bricks, pellets, rods and spheres

- Other dimensions/shapes on request

- Can be supplied machined to close tolerances

- Other boron loadings available on request

- Self-extinguishing version available (see model JC207)

Uses

Neutron Shielding

Linac Bunkers

Moderator

Instrument Shielding

Wall Shielding